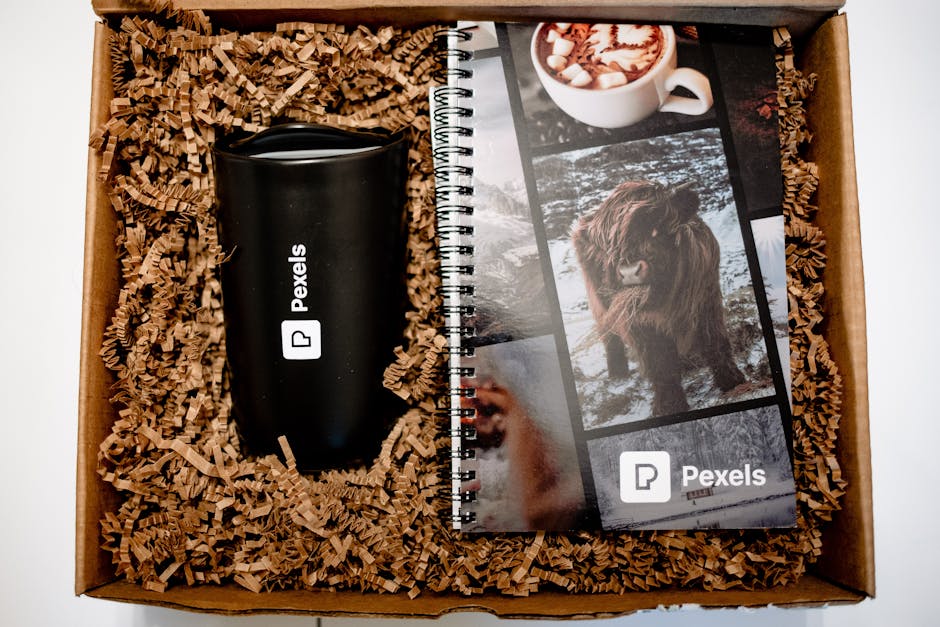

Smart custom box design is one of the fastest, lowest-risk ways Chinese brands can cut packaging costs without diluting brand image or customer experience.

With rising raw material prices, logistics costs and stricter regulations on excessive packaging in China, brands are under pressure to optimize every yuan they spend on boxes, fillers and printing.[8][10] The good news: thoughtful structural design, right-sized dimensions and smarter material choices can reduce your total packaging cost while keeping – or even improving – perceived value.[1][3]

This guide explains how you can redesign your custom boxes to save money across materials, printing and logistics, while still delivering a premium unboxing moment.

Why Packaging Costs Are Rising – And Where The Real Money Goes

When brands talk about “high packaging cost,” they often think only about the price of the box. In reality, your total packaging cost includes:

- Materials – board, inks, coatings, inserts, tapes, labels[1][3]

- Printing & finishing – plates, setup, special effects, wastage[1]

- Transport & warehousing – volumetric weight, pallet utilization, storage space[1][4]

- Handling & packing labor – assembly time, packing complexity, error rates[1][3]

- Returns & damage – broken products, reshipment, lost customer trust[1]

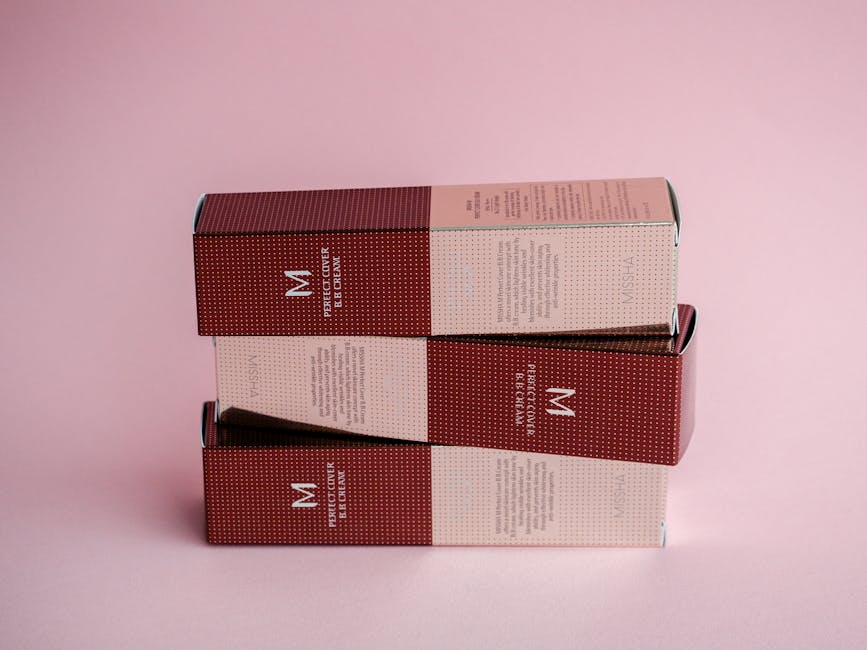

In China, regulations on excessive packaging for food, cosmetics and other categories are becoming stricter, pushing brands to remove unnecessary layers and void space.[8] At the same time, sustainable materials and recycled content are increasingly encouraged, creating both compliance and branding opportunities.[10]

Key takeaway: Smart box design is not just about a cheaper carton; it is about reducing cost at every stage – from board usage and printing to logistics, labor and damage rates – while staying compliant and on-brand.

1. Right-Size Your Boxes To Cut Material & Shipping Costs

Using boxes that are too large is one of the most common and expensive mistakes. Carriers and logistics partners often charge based on dimensional weight, so every extra centimeter of empty space adds cost.[1][4] Smaller, tighter boxes also reduce board consumption and filler usage.[1][3]

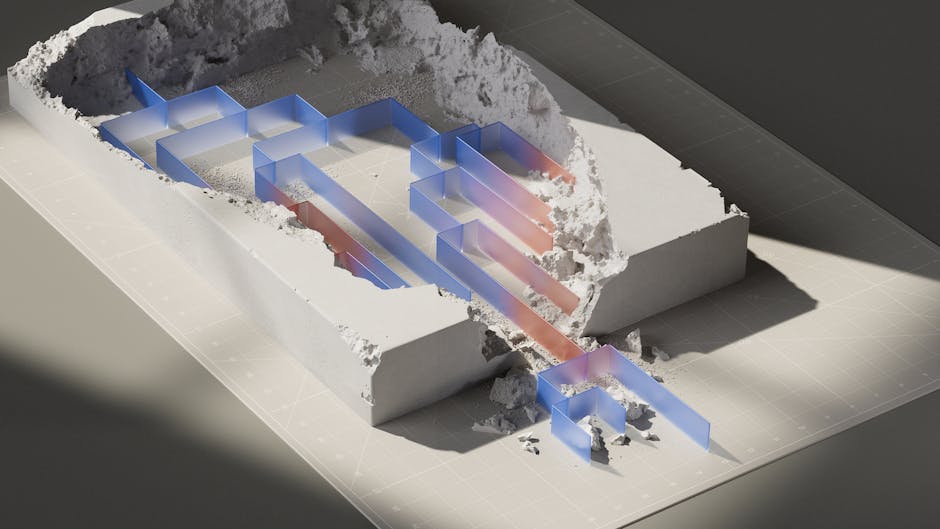

Design For Dimensional Efficiency

Brand owners can work with packaging engineers to match internal dimensions closely to the product or product set. Real-world cases show that simply shrinking dimensions by 1–2 cm on each side can move a parcel into a cheaper shipping tier and reduce material consumption at the same time.[1][4]

- Measure precisely – product, accessories, and any mandatory inserts

- Use slimmer walls where compression tests still pass performance standards[1]

- Stack and nest products efficiently to minimize void space[1][3]

Standardize Sizes Across SKUs

Instead of dozens of box sizes, many Chinese brands are moving to a modular size system so multiple products fit in the same outer carton.[1][3]

- 3–5 master sizes cover 80–90% of SKUs

- Shared inserts or adjustable dividers protect different products[1]

- Higher volumes per size lower unit cost and improve inventory control[3]

Key takeaway: Smaller, standardized boxes reduce board usage, fillers, shipping charges and storage space – a compound cost saving that does not hurt brand image when designed cleanly and precisely.

2. Simplify Structural Design Without Looking “Cheap”

Many brands in China still use multi-layer packaging structures: outer box, inner gift box, tray, lid, sleeve and multiple promotional cards. Regulations and consumer sentiment are both turning against this type of excessive packaging.[8][10]

Eliminate Non-Essential Components

Industry guidance shows that removing decorative but non-functional layers (such as unnecessary pouches, secondary sleeves, or duplicate lids) can significantly reduce cost and waste while maintaining functionality.[1][3]

- Combine functions – e.g., print instructions directly inside the lid instead of adding leaflets[3]

- Use integrated inserts die-cut from the same board as the box[1]

- Switch from multi-piece to one-piece structures that lock without tape or glue where feasible[1]

Prioritize Performance Testing Over “Over-Engineering”

Many brands add thickness or extra layers as “insurance,” which can quietly inflate costs. Simple in-house tests such as drop, stack, and compression testing help define the minimum board grade and structure you actually need.[1]

- Drop tests from realistic heights for e-commerce conditions[1]

- Stack tests to simulate warehousing and pallet loads[1]

- Handling tests to reflect real courier treatment[1]

Key takeaway: By engineering to proven performance instead of assumptions, brands can safely reduce board grades, remove redundant layers and simplify structures without increasing damage rates.

3. Optimize Materials: Where To Save And Where To Invest

Material choice has a direct impact on both unit price and logistics performance. The goal is to choose the lightest, thinnest, most sustainable material that still meets strength requirements and your brand positioning.[1][3][10]

Select Cost-Effective Board Grades

Switching from over-specified to appropriate board grades can reduce per-box cost and shipping weight.[1][3]

- Use testliner or recycled content where print needs are moderate[1][6][10]

- Reserve SBS / rigid box constructions for true hero SKUs or luxury lines[5]

- Mix materials intelligently – corrugated shipping box + premium printed sleeve or insert for branding

Leverage Recycled & Sustainable Materials

Recycled and responsibly sourced papers are increasingly competitive on price and strongly supported by Chinese and international policy trends.[1][10]

- Recycled corrugated often costs less than virgin while signaling eco-consciousness[1]

- Monomaterial designs (all paper-based) simplify recycling and can lower compliance costs[10]

- Eliminate plastics where possible to align with phase-outs of single-use components in global fashion and beauty segments[1][10]

| Material Option | Cost Level | Brand Perception | Best Use Case |

|---|---|---|---|

| Recycled corrugated (kraft) | Low–medium | Eco, natural, honest | E-commerce shippers, mid-range products |

| White coated corrugated | Medium | Clean, modern, versatile | Consumer retail boxes, subscription boxes |

| SBS folding carton | Medium–high | Premium, high print quality | Cosmetics, food, pharmacy |

| Rigid (set-up) box | High | Luxury, giftable | High-end electronics, luxury beauty, gifting |

Key takeaway: Use the minimum board grade that passes tests, maximize recycled content, and reserve high-end materials only for products where the uplift in perceived value or retail sales justifies the extra cost.[1][5][10]

4. Make Printing & Branding More Cost-Efficient

Strong branding does not have to mean expensive printing. Many cost drivers – number of colors, special finishes, separate labels – can be optimized without diluting brand recognition.[1][3]

Reduce Print Complexity

Each additional color, plate and process step adds make-ready time, waste and cost.[1][3]

- Limit spot colors and rely on 1–2 brand colors plus black[3]

- Print information directly on the box instead of separate stickers or leaflets[3]

- Use minimalist design – clean typography and negative space can look more premium than heavy graphics

Use Smart Finishes, Not Every Finish

Premium effects like foil, embossing and special coatings should be applied selectively to hero elements instead of the whole surface.

- Focus finishing on logo or key pattern to keep tooling small

- Swap full lamination for spot coatings or water-based varnish where suitable

- Consider one-color hot stamping on kraft for a luxurious yet economical look

Key takeaway: Strong, consistent branding relies more on clear visual hierarchy and recognisable assets than on expensive multi-color, multi-finish treatments.

5. Lower Logistics & Operational Costs Through Better Box Design

Cost savings from packaging design are magnified when they flow through logistics and operations. Chinese exporters are already redesigning packaging to optimize container loading and control rising shipping costs.[6]

Design For Pallet & Container Optimization

Small changes in box footprint can increase how many units fit on a pallet or in a container row.[1][6]

- Match outer box dimensions to common pallet sizes used in your export markets

- Use CAD layout simulations to maximize cartons per layer and per pallet

- Minimize overhang to reduce damage and comply with warehouse requirements

Simplify Assembly & Packing

Complicated structures slow down packing and increase labor costs.[1][3]

- Switch to auto-lock bottom or crash-lock designs for faster forming

- Reduce separate components packers must assemble or align

- Clearly mark orientation on the box exterior to cut handling errors

Key takeaway: A box that packs faster, stacks better and ships more densely generates ongoing savings every day it is used.

6. Work Closely With Your Packaging Partner

Cost-efficient custom packaging is easier when you treat your supplier as a strategic partner, not just a vendor. Suppliers who understand your product mix, logistics and brand priorities can proactively suggest smarter structures, materials and sizes.[1][3][7]<