“`html

Digital Printing Advancements for Short-Run Custom Packaging in 2025

Digital printing is revolutionizing short-run custom packaging, enabling brands to produce high-quality, personalized solutions with minimal waste and rapid turnaround. In 2025, the global digital printing for packaging market reaches $22.0 billion, representing 4.1% of all printed packaging, with projected growth of USD 16,060.4 million from 2025-2029 at a 9.9% CAGR[1][9]. This shift empowers e-commerce brands and retailers to meet demands for versioning, personalization, and sustainability without high setup costs.

For businesses launching limited-edition products or testing market designs, these advancements mean on-demand production that aligns perfectly with agile supply chains. Discover how 2025’s innovations in AI, inks, and smart integration are transforming your packaging strategy.

The Rise of Digital Printing for Short-Run Needs

Short-run custom packaging thrives on digital printing’s ability to handle low volumes economically. Unlike traditional offset methods, digital eliminates plates and setups, slashing costs for runs under 1,000 units. Brands now leverage this for seasonal promotions, personalized e-commerce boxes, and rapid prototyping[2][4].

Market data confirms the surge: 91% of brand owners use digital printing for at least some labels or packaging, with 39% deeming it essential in suppliers[4]. This adoption drives sales growth, as eye-catching, variable designs boost consumer engagement[1].

Key Takeaway: Digital printing’s speed and flexibility make it ideal for short runs, reducing inventory risks and enabling just-in-time production.

Key Technological Advancements Shaping 2025

AI-Driven Automation and Workflow Optimization

Artificial intelligence now manages color consistency, predicts maintenance, and optimizes scheduling in digital workflows[3][5]. For short-run packaging, AI ensures brand colors remain uniform across SKUs and regions, minimizing errors in high-mix production[1][3].

Prepress automation and IoT integration further streamline operations, offering traceability that appeals to global brands seeking transparency[3].

Printhead and Ink Innovations

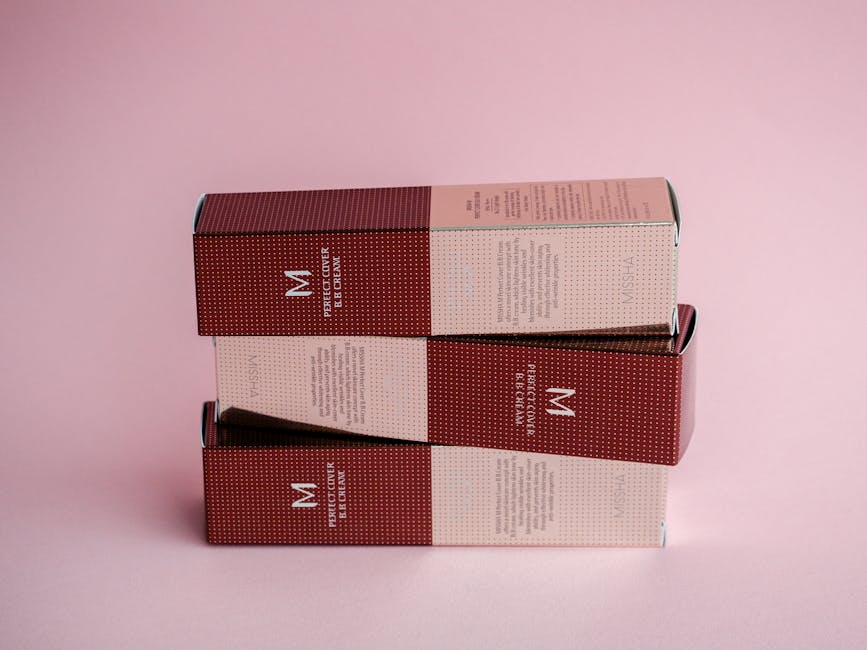

Advancements in inkjet printheads and formulations enhance durability, color gamut, and substrate compatibility[1][6]. UV inkjet printing provides resistance to sunlight and moisture, ideal for flexible packaging in food and cosmetics[1][2].

Water-based inks and eco-friendly options reduce environmental impact while maintaining vibrant prints, aligning with sustainability mandates[3].

Sustainable Practices in Digital Short-Run Printing

Sustainability defines 2025 digital printing, with waste minimization through on-demand runs cutting excess inventory[1][2]. Eco-friendly materials and inks support the shift from single-use plastics, driven by regional bans[1].

Brands achieve transparency via QR codes and blockchain for origin tracking, enhancing trust in custom packaging[2]. Short runs further lower the carbon footprint by producing only what’s needed.

| Traditional Offset | Digital Printing (2025) |

|---|---|

| High setup costs for short runs | Low/no setup; cost-effective for <1,000 units |

| Waste from plates and overproduction | On-demand; minimal waste |

| Long lead times | Fast turnaround (days vs. weeks) |

| Limited personalization | Variable data for unique designs |

Key Takeaway: Digital printing reduces waste by up to 90% in short runs compared to offset, supporting eco-goals without quality trade-offs[1].

Smart and Interactive Packaging Innovations

Integration of RFID, augmented reality (AR), and sensors turns packaging into smart experiences[1][3]. For short-run custom needs, variable data printing embeds these features economically, tracking freshness or enabling AR product info[1].

4D printing emerges as a frontier, where packaging changes shape with environmental triggers like heat—reducing shipping volumes for flat-packed custom boxes[3]. Active sensors in pharmaceuticals and food extend shelf life, cutting spoilage[2][3].

Applications Across Industries

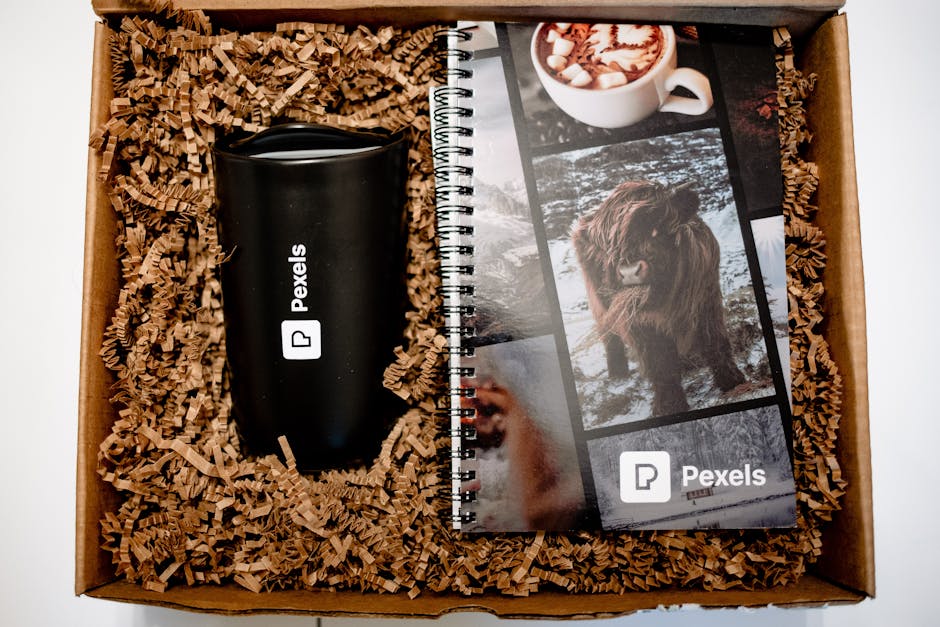

E-commerce leverages digital for branded boxes with personalization, while food and beverage use high-barrier flexible films[1][2]. Cosmetics benefit from color-optimized prints and embossing for premium feel[1].

- Food & Bev: Multi-layer films with digital labels for safety and traceability[2].

- Cosmetics: High-res versioning for limited editions[1].

- Pharma: Security features like RFID for anti-counterfeiting[1].

- E-commerce: Custom boxes enhancing unboxing experiences[4].

7 Practical Tips for Implementing Short-Run Digital Printing

- Choose UV Inkjet for Durability: Opt for UV-cured inks on flexible substrates to ensure longevity in retail environments[1].

- Leverage AI Color Management: Use AI tools for consistent branding across short runs and global SKUs[3].

- Incorporate Variable Data: Personalize with names or QR codes to boost engagement without added costs[2].

- Prioritize Eco-Materials: Select recyclable papers and water-based inks for sustainable appeal[6].

- Test Smart Features: Prototype RFID or AR in small runs for supply chain visibility[1][3].

- Integrate Finishing Techniques: Add embossing or foil for tactile premiumization post-print[1].

- Partner with Flexible Manufacturers: Seek low-MOQ providers expert in offset-to-digital hybrids for scalability.

Key Takeaway: Start with prototypes—digital’s low entry barrier lets you iterate designs quickly before scaling.

Quick Reference: Top 2025 Trends

- AI automation for flawless consistency[3][5].

- Inkjet durability and eco-inks[1][6].

- Smart packaging with sensors/AR[1][3].

- Short-run waste reduction[2].

- 4D printing for adaptive designs[3].

Looking Ahead

Digital printing advancements position short-run custom packaging as a competitive edge in 2025, blending innovation, sustainability, and personalization. Brands adopting these technologies report higher engagement and loyalty through standout unboxing experiences.

How will you integrate digital printing to elevate your packaging? Explore custom solutions that match your vision for quality and efficiency.

“`

_Disclaimer: Grok is not a lawyer; please consult one. Don’t share information that can identify you._