Extended Producer Responsibility: Navigating 2025 EPR Laws in Packaging

Extended Producer Responsibility (EPR) is reshaping how brands design, source, and report on packaging worldwide. In 2025, EPR laws for packaging have accelerated, especially in the United States, creating new obligations, costs, and opportunities for e-commerce brands and product manufacturers.[1][2][4]

For businesses that ship in boxes, mailers, and paper bags every day, EPR is no longer a future issue—it is a compliance requirement that touches materials, design, reporting, and fees at the same time. Understanding these rules now helps you avoid penalties and turn regulation into a competitive advantage.[2][5]

This guide explains what EPR is, where 2025 packaging laws apply, how they affect your packaging strategy, and how custom sustainable packaging can help you stay compliant while strengthening your brand.

What Is Extended Producer Responsibility in Packaging?

Extended Producer Responsibility (EPR) is an environmental policy approach that makes producers responsible—financially and often operationally—for the end-of-life management of their products and packaging.[1][2] Instead of municipalities bearing most waste costs, EPR shifts part of that burden to the companies that place packaging on the market.[5]

For packaging, “producers” are usually brand owners, manufacturers, importers, or licensees that sell products into a jurisdiction, with exemptions for very small businesses in some laws.[2] These companies must fund or support collection, sorting, recycling, and sometimes reuse systems.

Core elements of EPR for packaging

- Financial responsibility – Paying fees based on packaging material type, recyclability, and volume placed on the market.[2][5]

- Operational responsibility – In some systems, helping organize or fund collection, sorting, and recycling infrastructure.[1][5]

- Data and reporting – Submitting detailed packaging data (weights, materials, recyclability, recycled content, brands) each year.[2][5]

- Design incentives – Higher fees for hard-to-recycle packaging and lower fees for recyclable, reusable, or compostable formats.[2][4]

Key Takeaway: EPR directly links your packaging choices to your compliance costs—better-designed, more recyclable packaging generally means lower fees and lower regulatory risk.[2][5]

The 2025 EPR Landscape: Where Packaging Laws Apply

By late 2025, seven U.S. states have enacted comprehensive EPR programs focused on packaging and paper products: Maine, Oregon, Colorado, California, Minnesota, Maryland, and Washington.[3][4][6][7][10] Many other states are actively considering similar laws.[1][4]

Several of these programs enter critical implementation or reporting phases between 2025 and 2027, meaning producers must register, provide packaging data, and prepare for fees and design requirements.[2][4][7]

Current EPR packaging states and 2025 status

| State | Law & Focus | 2025–2027 Milestones (Selected) |

|---|---|---|

| Maine | First US packaging EPR law, broad packaging scope.[6][7] | Program build-out continues; stewardship organization selection process active into 2025.[2][4] |

| Oregon | Plastic Pollution and Recycling Modernization Act for packaging & paper.[3][7] | Program became fully implemented July 1, 2025; ongoing rulemaking and program plan amendments.[3] |

| Colorado | Statewide packaging EPR for paper & packaging.[2][6][7] | Producer registration requirements in place; program ramping toward operational timelines through late 2020s.[2][8] |

| California | SB 54 targeting all single-use packaging and plastic foodware, with recyclability/compostability goals by 2032.[2][4] | Preliminary reporting due November 2025; PRO program plan mid‑2026; program operation by 2027.[2][4] |

| Minnesota | Packaging EPR with phased cost coverage by producers.[2][4] | PRO registration by July 1, 2025 and progressive cost coverage through 2031.[2] |

| Maryland | 2025 law allowing multiple Producer Responsibility Organizations and incentivizing recyclable/reusable/compostable packaging.[4] | Program design and rulemaking underway after May 2025 enactment.[2][4] |

| Washington | 2025 law focused on consumer packaging, expanding collection services and cutting recycling costs over time.[4] | Producer deadlines begin 2026; phased cost coverage increases through 2032.[2][4] |

In parallel, multiple other states—including New Jersey and Tennessee—have actively considered packaging EPR legislation, signaling that the EPR model will likely expand further across the US.[4][7][10]

Key Takeaway: If you sell into the US, you should plan for EPR compliance in at least seven states today—and assume more jurisdictions will adopt similar packaging rules over the next few years.[4][6][7]

How EPR Changes Packaging Strategy for Brands

EPR laws do not only add administrative tasks; they change the economics of packaging. Fees are typically “eco‑modulated,” meaning they are higher for non-recyclable, toxic, or hard‑to‑process materials and lower for recyclable or reusable packaging.[2][5][9]

For e-commerce brands and manufacturers, this makes your paper boxes, bags, mailers, and void fill part of a financial and regulatory equation—every gram and every substrate counts.

Key impacts on your packaging decisions

- Material selection – Laws increasingly favor recyclable paper and cardboard over complex multi-material plastics.[2][4][9]

- Design for recyclability – Simpler mono-material structures, minimal mixed laminates, and easily removed labels/tapes are incentivized.[2][5]

- Source reduction – Many programs include targets or expectations for reducing overall packaging weight and volume.[2][4][9]

- Reuse and refill – Some EPR frameworks offer bonuses or fee reductions for reusable or refillable packaging systems.[3][4]

- Reporting readiness – You will need traceable data on material types, weights, recycled content percentages, and volumes by market.[2][5]

Because fees are based on the amount and recyclability of your packaging, investing in lighter, right-sized, and more recyclable packaging can offset some of the new cost burdens.[2][5][9]

Key Takeaway: Under EPR, sustainable packaging is no longer only a CSR initiative—it is a cost-control and compliance strategy that directly affects your bottom line.[2][5]

The Role of Producer Responsibility Organizations (PROs)

Most EPR systems centralize producer obligations through a Producer Responsibility Organization (PRO)</strong). Producers register with a PRO, report their packaging data, and pay fees that the PRO uses to fund collection and recycling.[2][5]

In the US, Circular Action Alliance (CAA) has been approved as the PRO in several states, including California, Colorado, Maryland, Minnesota, and Oregon, and is also participating in Maine’s stewardship process.[2][3][8]

What producers must typically do via a PRO

- Determine producer status for each jurisdiction and product (brand owner, importer, etc.).[2][5][7]

- Register with the designated PRO(s) by state-specific deadlines.[2][3][8]

- Submit packaging data annually, including:

- Material type (e.g., corrugated board, kraft paper, plastics)[2][5]

- Weight and volumes placed on the market[2][5]

- Recycled content and recyclability status[2][5]

- Brand names and packaging formats[5]

- Review fee schedules and eco-modulation criteria to understand cost drivers.[2][5]

- Adjust packaging designs over time to reduce fees and improve compliance.[2][4][5]

Key Takeaway: Accurate packaging data is the backbone of EPR compliance—if you cannot measure your materials, you cannot manage your legal obligations or optimize your fees.[2][5]

Designing Packaging for EPR Compliance and Brand Value

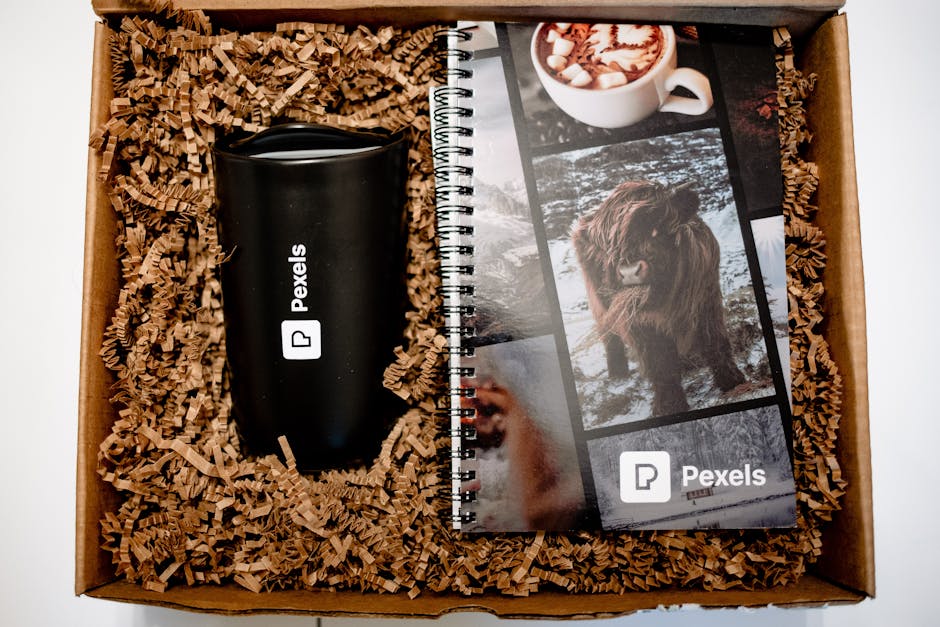

EPR does not mean compromising your unboxing experience. It means aligning design, materials, and brand storytelling with recyclability, reduction, and responsible sourcing. This is where custom packaging partners become strategic.

By working with a manufacturer that specializes in custom printed paper boxes, mailers, and bags, you can tailor packaging to both regulatory and marketing needs—meeting EPR-driven recyclability criteria while delivering a premium, on-brand look.

Packaging features that support EPR goals

- Mono-material paper structures – Boxes and mailers made from a single fiber-based material (e.g., corrugated or kraft) are easier to recycle and often favored under EPR schemes.[2][4][9]

- Responsible inks and coatings – Water-based inks and recyclable-friendly coatings help maintain fiber quality and recyclability.

- Right-sized design – Custom die-cut boxes reduce void space and material usage, supporting source reduction objectives.[2][4]

- Clear recyclability messaging – Printed instructions and standardized recycling icons increase actual recovery rates and demonstrate compliance intent.

- Recycled content – Using post-consumer or post-industrial recycled fiber can support circularity targets embedded in some EPR systems.[2][5][9]

Techniques such as offset printing, embossing, debossing, and foil stamping can still be used strategically on recyclable substrates to maintain a premium brand image while staying aligned with EPR expectations.

Key Takeaway: EPR-compatible packaging is not just “brown and basic”—thoughtful structural design and premium printing on recyclable paperboard can deliver both compliance and a memorable customer experience.

Practical Steps to Prepare Your Packaging for 2025+ EPR Laws

Whether you are an emerging e-commerce brand or a global manufacturer, you can build an EPR-ready packagin

Permalink