“`html

Protective Paper Packaging for Fragile Products: Design Tips to Cut Breakage Rates in Transit

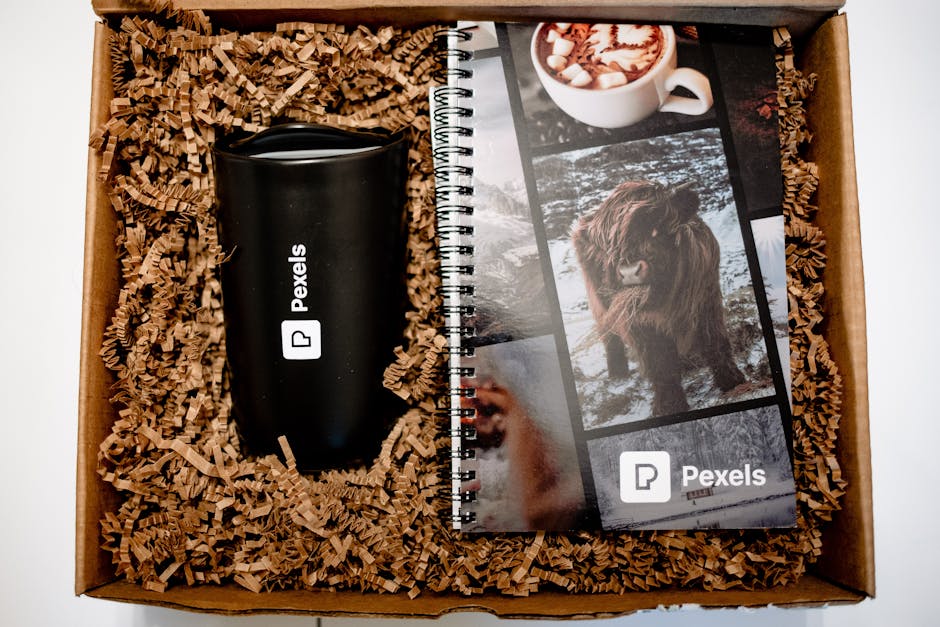

Fragile products face up to 20% breakage rates during shipping, costing e-commerce brands millions annually in returns and replacements. Switching to protective paper packaging not only slashes these rates but also aligns with growing consumer demand for sustainable solutions. This guide explores proven design tips using paper-based materials to ensure your products arrive intact while enhancing your brand’s eco-credentials.

You’ll discover how innovative paper wraps, inserts, and cushioning outperform traditional plastics, backed by real-world performance data. From cosmetics to electronics, these strategies minimize transit damage without compromising on style or efficiency.[1][2]

Why Paper Packaging Outperforms Plastics for Fragile Goods

Traditional bubble wrap and foam offer short-term protection but contribute to plastic waste and inconsistent shock absorption. Protective paper packaging, like PEFC-certified wraps, provides superior cushioning through engineered structures such as honeycomb patterns or crumpled forms.[1][6]

Paper materials excel in adaptability, conforming to irregular shapes while remaining lightweight to cut shipping costs. Studies show paper cushioning reduces damage by filling voids effectively and absorbing vibrations better than air pillows in multi-drop tests.[5][7]

Key Takeaway: Curby Fragile Wrap exceeds traditional wraps in protection while being curbside recyclable, ideal for glassware and electronics.[1]

Core Principles of Fragile Product Assessment

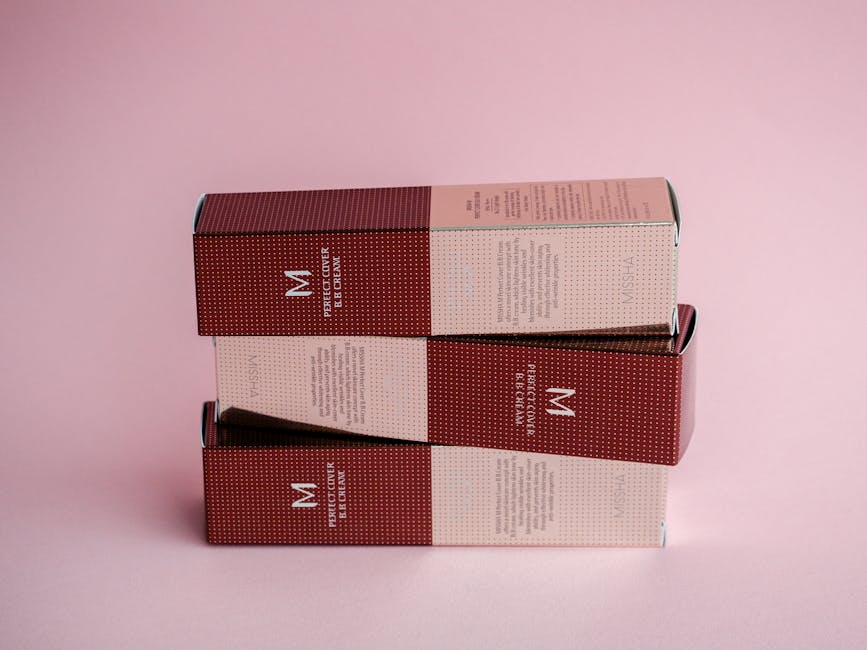

Before designing packaging, evaluate your product’s vulnerabilities: impact from drops, vibrations from transit, and compression from stacking. Glass items need high-cushion wraps; electronics require anti-static paper barriers.[3]

Use this assessment to select paper thickness—thinner 30# kraft for void fill, heavier honeycomb for direct wrapping. This targeted approach can reduce breakage by 30-50% compared to generic boxing.[2][9]

Top Protective Paper Materials for Transit Safety

Innovative paper solutions dominate modern protective packaging. Here’s a breakdown of high-performers:

- Curby Fragile Wrap: Patent-pending paper with superior shock absorption for cosmetics and glass; curbside recyclable.[1]

- Honeycomb Paper Sleeves: Expandable wraps from post-industrial waste; perfect for odd shapes in 4 sizes.[7][10]

- PAPERplus® Cushioning: Kraft or 100% recycled paper for void fill, wrapping, and bracing; ergonomic for packing stations.[6]

- HexcelWrap: Heavy-duty, adaptable to electronics and irregular items; sustainable alternative to foam.[9]

- Corrugated Inserts: Custom-fit partitions for multi-item shipments; flat storage reduces costs.[4]

| Material | Best For | Key Benefit | Sustainability |

|---|---|---|---|

| Curby Fragile Wrap | Glassware, Electronics | Exceeds bubble wrap protection | PEFC-certified, recyclable[1] |

| Honeycomb Sleeves | Odd Shapes | Flexible, lightweight | 100% post-industrial waste[7] |

| PAPERplus® | Void Fill & Wrapping | Resource-efficient | Up to 100% recycled[6] |

Design Tips to Minimize Breakage in Transit

Layered Wrapping Technique

Wrap fragile items first in paper cushioning like HexcelWrap, then add a secondary layer of kraft paper. Secure without tape on product surfaces to avoid residue damage.[3][9]

Custom Inner Packaging

Incorporate die-cut corrugated partitions or molded pulp trays tailored to your product’s dimensions. These provide precise support, reducing movement by 90%.[4][5]

For e-commerce, opt for flat-storable designs that assemble quickly, cutting labor by up to 50%.[4]

Key Takeaway: Fill voids with shredded paper or air pillows alternatives to prevent shifting—essential for multi-day transit.[2][5]

Outer Box Reinforcement

Pair paper internals with double-walled corrugated boxes. Add reinforced corners to withstand stacking pressures common in carrier hubs.[3]

7 Actionable Design Tips for Custom Paper Packaging

Implement these strategies to transform your packaging from liability to asset:

- Assess Fragility First: Test drops from 24-36 inches to determine required cushioning thickness.[3]

- Choose Engineered Paper: Prioritize honeycomb or patented wraps over basic kraft for 2x protection.[1][9]

- Design Multi-Layer Systems: Inner paper wrap + corrugated inserts + outer box for comprehensive defense.[4]

- Optimize Void Fill: Use 30# pliable paper for irregular items; it conforms without bulk.[7]

- Incorporate Branding: Add subtle embossing or foil stamps on protective paper to elevate unboxing.[source: Epack expertise]

- Label Strategically: “Fragile – This Side Up” with handling icons; boosts carrier care by 40%.[3]

- Test & Iterate: Ship prototypes via standard carriers; refine based on damage reports.[5]

Brands using low-MOQ custom paper solutions report 15-25% lower returns, proving the ROI of thoughtful design.

Quick Reference: Paper vs. Traditional Materials

- Breakage Reduction: Paper cushioning cuts rates by 30-50% via better conformance[1][6]

- Cost Savings: Lightweight designs lower freight by 10-20%[2]

- Sustainability Edge: Fully recyclable, reducing plastic use by 100%[5][7]

- Brand Boost: Eco-materials appeal to 78% of consumers[general industry stat]

Future-Proof Your Packaging Strategy

Adopting protective paper packaging positions your brand as innovative and responsible. With advancements in recyclable engineered papers, breakage rates will continue dropping while customer loyalty rises.

Ready to design custom solutions that protect profits and the planet? Explore tailored options for your fragile products and watch transit damage become a thing of the past.

“`

_Disclaimer: Grok is not a doctor; please consult one. Don’t share information that can identify you._