Sustainable materials are no longer a niche option in packaging—they are rapidly becoming the standard that regulators, retailers, and consumers expect from every brand.

For Epack clients, understanding the shift toward bio-based plastics and advanced recyclable materials is critical to future-proof your packaging, protect margins, and strengthen your brand’s sustainability story.

This article explains what is changing, which materials matter most, and how you can practically integrate them into your custom packaging with low risk and high impact.

The Sustainable Materials Revolution in Packaging

Fossil-based plastics still dominate global packaging, but bio-based and recyclable alternatives are scaling quickly as regulations tighten and consumers demand low-impact solutions.[1][5] Bioplastics currently account for about 0.5% of total plastics, yet production capacity is projected to double from 2.31 million tonnes in 2025 to 4.69 million tonnes by 2030.[5]

For e-commerce and retail brands, this means more options, better performance, and growing pressure to choose materials that align with circular economy goals and emerging standards like the U.S. Plastics Pact, which targets 30% recycled or responsibly sourced bio-based content in plastic packaging by 2025.[7]

Key takeaway: Bio-based and recyclable materials are moving from “nice-to-have” to “license-to-operate” in packaging, and early adopters will be best positioned with regulators, retailers, and consumers.

Bio-Based Plastics 101: What Epack Clients Need to Know

Bio-based plastics are polymers made from renewable feedstocks such as sugarcane, corn starch, and cassava instead of fossil fuels.[1][10] Chemically, many are similar to conventional plastics, but they can significantly reduce cradle-to-gate greenhouse gas emissions when responsibly sourced.[1][5]

Major bio-based packaging polymers in use or scaling today include:

- Bio-PET – Drop-in alternative to PET, often used in bottles and films; partially or fully derived from renewable plant sources.[1][5]

- PLA (Polylactic Acid) – Compostable bioplastic made from fermented plant sugars, widely used in clear trays, clamshells, and coatings.[1][2]

- Bio-PE – Polyethylene produced from sugarcane ethanol, used for films and flexible packaging.[1]

- PHA – A family of bio-based, biodegradable polyesters increasingly used in films and coatings, with new amorphous grades like PHACT A1000P designed for packaging applications.[4][5]

According to an IEA Bioenergy analysis cited in 2025 packaging innovation reviews, switching 25% of plastic packaging to bio-based alternatives could cut global packaging-related emissions by about 200 million tonnes CO₂e annually.[1]

Key takeaway: Bio-based plastics can dramatically lower fossil carbon use and emissions, but brands must match the right polymer to the right application and end-of-life pathway.

Next-Generation Bio-Based Films and Coatings

One of the fastest-moving areas for Epack’s clients is bio-based films and coatings that can replace or reduce traditional plastic laminates while preserving barrier performance.

Recent research highlights several breakthroughs that are highly relevant for paper-based and hybrid Epack solutions:

Spray-Coated Bioplastics on Paper

Researchers at Virginia Tech have developed a spray-coated bioplastic system that forms durable, compostable films on paper packaging.[2] By blending PLA with PHA, they created multilayer coatings that significantly improve strength, oxygen resistance, and water resistance while maintaining biodegradability.[2]

In their tests, spray-coated papers were up to twice as strong as uncoated paper and showed dramatically lower oxygen transmission, which is critical for food and sensitive product packaging.[2] Importantly, the process is designed to integrate into existing paper production and converting systems, enabling scalable adoption.[2]

Plant-Based Barrier Films as Plastic Alternatives

Georgia Tech researchers have developed a fully bio-based film from plant-derived components that can match or exceed the moisture and oxygen barrier performance of common plastics like PET and EVOH, even at high humidity.[3]

These films use abundant, biodegradable ingredients and are engineered to keep food fresh and safe without persisting in the environment for centuries.[3] The combination of strong mechanical properties and low oxygen permeability makes them a promising alternative for flexible packaging.[3]

Key takeaway: Advanced bioplastic coatings and films now allow paper-based packaging to achieve plastic-like barrier performance while staying compostable or recyclable by design.

Recyclable Materials: Designing for Circularity

While bio-based plastics are growing rapidly, recyclable materials remain the backbone of practical circular packaging strategies for many Epack clients. The focus is shifting from “is this recyclable in theory?” to “does this design work in real recycling systems?”

Key recyclable material platforms include:

- Mono-material paperboard – Custom printed boxes, mailers, and sleeves designed for fiber recycling streams, sometimes with ultra-thin or water-soluble barrier layers.[2][9]

- Mono-material plastic films – PE-only or PP-only structures designed to be compatible with existing recycling streams where available.[5][6]

- Recycled-content substrates – Boards and papers incorporating post-consumer fiber, aligned with targets for minimum recycled content in major markets.[7][8]

Industry roadmaps such as the U.S. Plastics Pact require that 100% of plastic packaging be reusable, recyclable, or compostable, and that at least 30% of plastic packaging content be recycled or responsibly sourced bio-based by 2025.[7] Epack clients that move early to mono-material and high-recycled-content designs will be better prepared for these thresholds.

Bio-Based vs. Traditional Plastics: At-a-Glance Comparison

To choose the right path for your packaging, it helps to compare conventional fossil-based plastics with bio-based and recyclable alternatives on key criteria.

| Aspect | Traditional Fossil Plastics | Bio-Based Plastics | Recyclable Paper / Mono-Material Films |

|---|---|---|---|

| Feedstock | Crude oil / natural gas | Renewable biomass (sugarcane, corn, seaweed, etc.)[1][4] | Wood fiber or single-polymer plastics |

| Carbon footprint | High fossil carbon emissions | Lower cradle-to-gate emissions when sustainably sourced[1][5] | Low to moderate; often improved with recycled content[7] |

| End-of-life | Mostly landfill / leakage; limited recycling | Recyclable or compostable depending on polymer and system[1][10] | Widely recyclable in established streams; some compostable papers[2][9] |

| Barrier performance | High; well-established | Rapidly improving via blends, coatings, and films[2][3] | Enhanced with bio-based coatings and functional barriers[2][3] |

| Regulatory outlook | Increasingly restricted (single-use bans, taxes)[6][8] | Encouraged where aligned with circularity goals[5][7] | Strongly favored in most sustainable packaging policies[7][8] |

Key takeaway: There is no single “best” material—optimal solutions often combine recyclable paper structures with targeted bio-based coatings or films to balance performance, cost, and circularity.

Market Momentum: Why This Matters for Your Brand Now

Multiple indicators show that the sustainable materials shift is not temporary but structural:

- Bioplastics capacity doubling – Global bio-based plastics production is forecast to rise from 2.31 to 4.69 million tonnes between 2025 and 2030, with packaging as the leading application.[5][6]

- Rapid growth in advanced polymers – Bio-based polypropylene and PHA are projected to increase their production shares severalfold by 2030, reflecting strong demand from packaging and related sectors.[5]

- Innovation awards and investment – Materials like PHACT A1000P and seaweed-derived films are being recognized by major industry associations and scaled for high-volume extrusion.[4]

At the same time, governments and coalitions are tightening expectations around recyclability, recycled content, and bio-based inputs, making “business as usual” packaging increasingly risky.[6][7][8] Epack clients who upgrade materials early can reduce compliance risk and differentiate with retailers seeking low-impact suppliers.

Practical Material Strategies for Epack Clients

To turn this material revolution into a competitive advantage, brands can adopt a staged, data-driven approach rather than switching everything overnight.

1. Map Your Current Material Footprint

- List all packaging SKUs by material type (paperboard, plastic film, laminates, mailers).

- Identify where multi-layer, hard-to-recycle structures are used.

- Prioritize high-volume SKUs and markets with strong regulatory or retailer pressure.

2. Shift Low-Risk SKUs to Recyclable Paper-Based Solutions

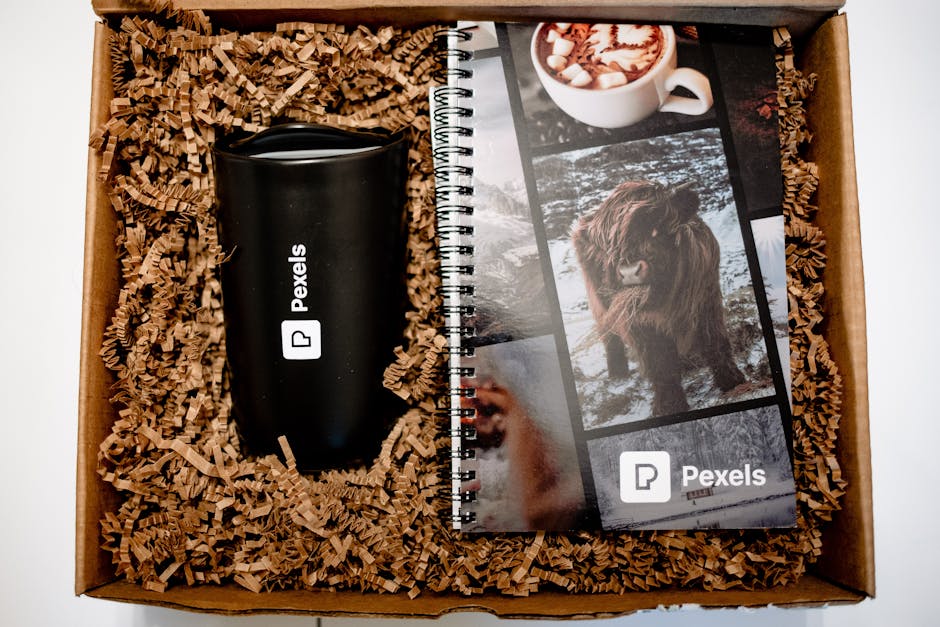

Start with products that do not require extreme moisture or oxygen barriers—such as apparel, accessories, home goods, or certain dry products. Replace mixed-material packs with custom printed paper boxes, mailers, and sleeves designed for fiber recycling.

Epack’s capabilities in offset printing, die-cutting, embossing, and foil stamping allow you to maintain premium branding while simplifying material structures for recyclability.

3. Add Bio-Based Coatings Where Higher Performance Is Needed

For products that need better moisture or grease resistance, consider paperboard combined with bioplastic coatings like PLA/PHA blends or other compostable barrier layers inspired by recent research.[2][3]

This hybrid approach allows you to keep a paper core (for recyclability or compostability) while reducing or replacing fossil-based laminates.

4. Test Bio-Based Films for Flexible and Food-Adjacent Applications

If you rely on flexible packaging, explore emerging plant-based barrier films that can match PET or EVOH performance.[3][9] Pilot them first on targeted SKUs, focusing on shelf-life, machinability, and consumer perception.

5. Design for Realistic End-of-Life Scenarios

Choose between recycling, industrial composting, home composting, or reuse based on what your main markets can realistically support. A theoretically compostable film has limited impact if local composting infrastructure is rare.[1][10]<

Recommended Reading

- **2025 Sustainable Packaging Trends: How Epack’s Paper-Based Solutions Help Brands Comply with EPR Laws and Reduce Plastic Waste**[1][2][5]

- التغليف الذكي والتفاعلي: دمج RFID وNFC لتعزيز الشفافية وتتبع المنتجات[3][4][5]

- Fiber-Based vs. Plastic Packaging: What International Buyers Should Know Before Sourcing from China